WHAT IS A SELECTIVE CATALYTIC REDUCTION SYSTEM?

Selective Catalytic Reduction (SCR) is a method used in the conversion of nitrogen oxides into diatomic nitrogen and water by using a catalyst. Urea is added to the exhaust gas and adsorbed onto the catalyst used. Safety Power Inc. specializes in designing these systems to help combat emissions, making the environment cleaner. With the eco cube TM brand, solutions to regulatory environmental requirements are achieved by Safety Power.

The ecoCUBE TM has been developed using Computational Fluid Dynamics (CFD) to achieve the highest possible reductions in levels of NOx emissions. The system has been designed to ensure maximum efficacy in the smallest space with the lowest possible levels of backpressure for the engine. The ecoCUBE TM SCR system is ideally suited to engines from 500HP to 5000HP to reduce nitrogen oxide emissions by up to 98%. It uses sophisticated sensor-based closed-loop feedback controls to ensure exceptional NOx control even when engine load changes significantly.

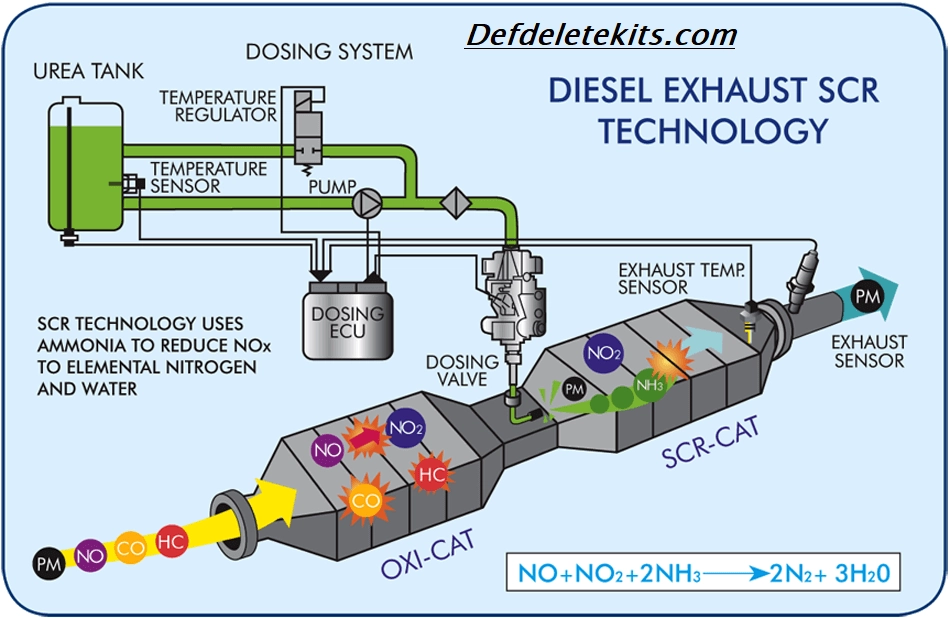

How SCR Works

Selective Catalytic Reduction uses basic chemistry to reduce NOx emissions through a process that is simple, extremely efficient, very reliable, and safe. The major components of the process are hot exhaust, Diesel Exhaust Fluid, and a catalytic converter.

Vaporized DEF and hot exhaust gases enter a catalytic converter located in the exhaust system after the diesel particulate filter. The catalytic converter contains a catalyst, which is a substance that causes or accelerates a chemical reaction, without being affected itself. [Catalysts are common in everyday life; for example, gasoline-powered vehicles have used catalytic converters to control emissions for several decades.]

DEF is a solution of purified water and urea, an organic nitrogen compound that turns to ammonia when heated. When this urea and water solution is injected into the hot exhaust stream and comes in contact with the SCR catalyst, the ammonia created from urea reacts with NOx to form nitrogen and water vapor — two clean and harmless components of the air we breathe.

Selective Catalytic Reduction (SCR) is one of the most cost-effective and fuel-efficient vehicle emissions control technologies available to reduce diesel engine emissions. For passenger cars and light-duty trucks, the ability to meet strict emissions and fuel efficiency guidelines affordably without compromising driving power and performance is attractive. In commercial trucking, the ability to reduce emissions to near-zero levels while also delivering a 3-5% fuel saving distinguishes SCR as one of the only emissions control technologies that are as good for business as it is for the environment.

SCR technology is designed to permit nitrogen oxide (NOx) reduction reactions to take place in an oxidizing atmosphere. The reducing agent reacts with NOx to convert the pollutants into nitrogen, water, and tiny amounts of carbon dioxide (CO2) – natural elements common to the air we breathe every day. The reductant source is usually automotive-grade urea, otherwise known as Diesel Exhaust Fluid, which can be rapidly hydrolyzed to produce the oxidizing ammonia in the exhaust stream. SCR technology alone can achieve NOx reductions in excess of 90%.

SCR will reduce:

- NOx emissions by up to 90%

- Hydrocarbons (HC) and carbon monoxide (CO) emissions by 50-90%

- Particulate matter (PM) emissions by 30 – 50%

Using Diesel Exhaust Fluid (DEF) to convert NOx emissions into pure nitrogen and water vapor, two natural components of the air we breathe, SCR systems can also be combined with a diesel particulate filter (DPF) to achieve even great emissions reductions for PM.

Further Reading: