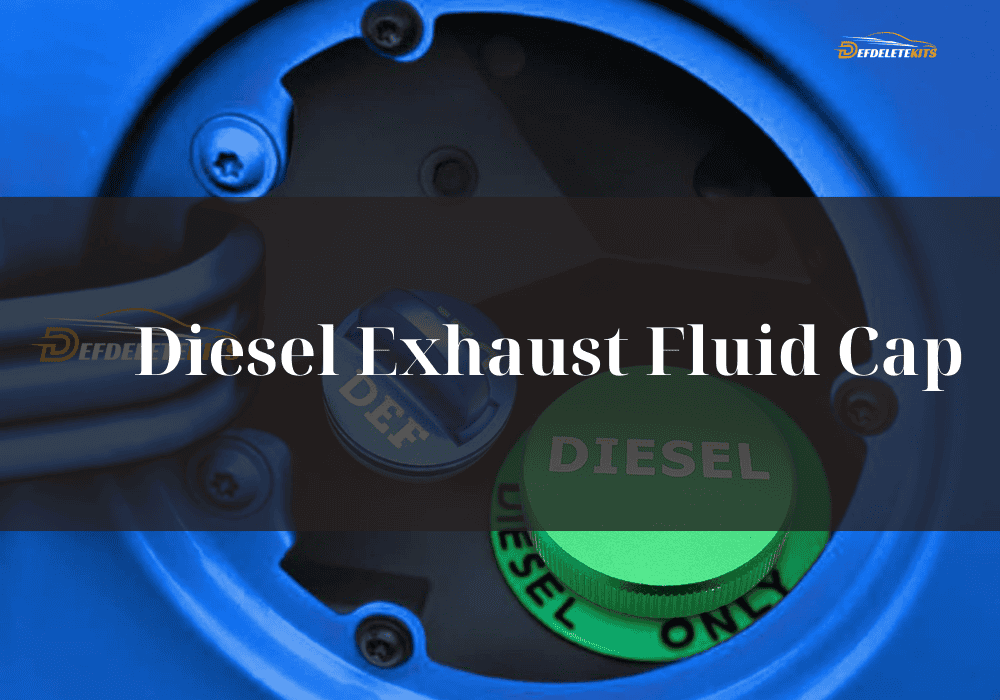

Learn about common Diesel Exhaust Fluid Cap issues that cause leaks, the signs it’s time for replacement, proper technique for installing a new cap, and maintenance tips to extend cap lifespan.

Diesel exhaust fluid (DEF) is a key component of selective catalytic reduction (SCR) systems used to reduce nitrogen oxide (NOx) emissions from diesel engines. While DEF helps diesel vehicles meet increasingly stringent emissions regulations, the caps that seal DEF tanks can sometimes cause issues.

This comprehensive guide covers everything you need to know about diesel exhaust fluid caps, including common problems, replacement tips, and ways to prevent leaks. By understanding DEF caps better, vehicle owners can help keep SCR systems functioning properly to reduce emissions and pass inspections.

What is DEF and Why is the Cap Important?

Diesel exhaust fluid is an aqueous urea solution that is sprayed into a vehicle’s exhaust stream. There, a catalytic converter uses the DEF to convert NOx gases into harmless nitrogen and water vapor. Modern diesel engines rely on SCR technology and DEF to lower NOx emissions to legally required levels.

The DEF tank and cap play crucial roles in the SCR system. The sealed tank holds the fluid used for emissions reduction. The cap acts as the barrier preventing evaporation and contamination. It must form an airtight seal to keep DEF fresh and allow proper dosing. Caps that leak or fail to seal correctly can cause DEF shortage issues, dashboard warning lights, and even disable the vehicle.

Common Diesel Exhaust Fluid Cap Problems

Over time, DEF caps can develop problems that compromise the seal. Some frequent issues owners encounter include:

- Cracks or splits – Plastic caps may crack from heat cycling or general wear. Cracks let air in, causing DEF to evaporate from the tank.

- Loosening or coming off – Vibration from driving can cause a worn cap to loosen or disconnect entirely from the tank neck.

- Warping or deformation – Heat exposure may cause the cap to warp out of shape, preventing a proper seal against the tank rim.

- Worn or damaged threads – Repeated use can wear down threads that secure the cap, compromising the seal. Dirt or corrosion on threads also hinders sealing.

- Missing o-ring or gasket – Internal sealing rings deteriorate over time, no longer creating an airtight barrier.

Any of these defects allow air into the DEF tank, accelerating fluid loss through evaporation. This can trigger warning lights and potentially disable the vehicle if levels get too low.

Signs It’s Time for a New DEF Cap

Several indications point to the need for DEF cap replacement:

- Dashboard warning lights for low DEF level or emissions system faults

- Difficulty fully tightening the cap onto the tank

- Evidence of leaking fluid around the cap-tank connection

- Prematurely low DEF tank level between fill-ups

- Visible cracks, splits, warping, or other physical defects

Replacing a faulty cap helps restore the sealed tank environment needed by the SCR system. It also prevents further DEF loss that could cause driveability or inspection check engine light issues down the road.

Tips for Replacing a DEF Cap

Proper DEF cap replacement follows these basic steps:

- Inspect the old cap – Check for signs of damage like cracks before removing.

- Remove the old cap – Turn it counterclockwise while gripping the tank. Wipe away any residual fluid or debris from the tank rim.

- Clean the tank rim – Use a rag to wipe away dirt or residue that could interfere with the new cap’s seal.

- Install the new cap – Hand-tighten it clockwise until snug against the tank. Do not over-tighten.

- Check for leaks – Inspect the cap-tank connection after driving for leaks. Retighten if needed.

- Top off DEF levels – Refill the tank as needed to restore the proper fluid level.

Proper installation is key to ensuring the new cap forms an effective seal. Take care not to over-tighten which could warp or damage the cap over time.

Preventing Future DEF Cap Issues

While caps will eventually need periodic replacement, some practices can extend their lifespan:

- Clean the cap and tank rim regularly – Wipe away dirt, salt or other residues.

- Avoid over-tightening the cap – Hand-tighten only until snug to prevent warping or cracking.

- Inspect for leaks periodically – Check the cap seal for signs of seepage, and retighten if loose.

- Replace caps showing wear – Don’t wait for leaks to occur if physical defects are visible.

- Store vehicle in a garage if possible – Shelter from extreme heat or cold extends component life.

- Use OEM replacement caps – Aftermarket caps may not seal as effectively long-term.

Proactive cap maintenance and replacement of worn parts helps keep DEF tanks sealed to support emissions system function for the life of the vehicle.

Conclusion

As essential components of diesel SCR technology, DEF caps require periodic inspection and replacement to maintain an airtight tank seal. Understanding common cap issues equips owners to recognize signs of failure. With proper replacement technique and preventive maintenance, DEF caps can provide long-term protection of the emissions reduction fluid level needed for diesel drivability and emissions compliance.