How To Choose and Use a Diesel Compression Tester?

If you’re looking for a diesel compression tester, there are a few things you’ll want to keep in mind to ensure you’re choosing the right tool for the job. In this article, we’ll walk you through how to select and use a diesel compression tester so that you can get accurate readings on your engine’s performance.

When it comes to choosing a diesel compression tester, you’ll want to consider the following factors:

– The size of the engine being tested: Make sure that the tester you choose is rated for engines of the same size as the one you’re testing. This will ensure accuracy of results.

– The type of connection: There are two basic types of connections – direct and indirect. Direct connections are more common and involve a hose that connects the compression tester directly to the engine’s cylinder head. Indirect connections use a manifold adapter, which is placed between the cylinder head and the tester. Most engines will use one of these two types of connections, so make sure you select the right type for your vehicle.

– The features offered: Some diesel compression testers offer additional features such as gauges or data logging capabilities. If you’re looking for a tool that offers more features, be sure to select one that has them.

Once you’ve selected a diesel compression tester, there are a few things you’ll need to do to ensure accurate readings:

– Clean the engine’s cylinders: Dirt and debris can interfere with the accuracy of compression readings. Be sure to clean the cylinders before taking any measurements.

– Remove the spark plugs: It’s important to remove the spark plugs from the engine before testing, as they can create a false reading.

– Connect the tester correctly: Make sure that you connect the tester properly to the engine – there are specific instructions for each type of connection. Failing to connect it correctly can cause inaccurate readings.

Once you have all of these steps in place, you’re ready to start taking compression readings. Here are a few tips on how to do so accurately:

– Start with the low cylinders: The low cylinders are typically those closest to the front of the engine. It’s best to start with these cylinders and work your way up to the high ones.

– Take multiple readings: It’s important to take several readings for each cylinder and average them together to get an accurate reading.

– Use the right compression range: Be sure to use the correct compression range for your engine. This can be found in the tester’s instruction manual.

When you are looking to buy a diesel compression tester, there are a few things that you need to keep in mind. Here are some tips on how to choose and use a diesel compression tester:

- Choose the right model for your needs. There are different models of diesel compression testers available on the market, so you need to make sure that you choose the right one for your needs. If you are only going to be using it occasionally, then a less expensive model should suffice. However, if you plan on using it regularly, then you might want to invest in a more expensive model that will last longer and provide more accurate results.

- Make sure that the tester is compatible with your vehicle. Not all diesel compression testers are compatible with all vehicles. Be sure to check the compatibility before you make your purchase.

- Read the instructions carefully. It is important that you read the instructions carefully before using the diesel compression tester. This will help ensure that you are using it correctly and getting accurate results.

- Follow the proper safety procedures. When using a diesel compression tester, it is important to follow the proper safety procedures. This will help avoid any potential accidents or injuries.

- Use quality parts and accessories. When purchasing a diesel compression tester, be sure to use quality parts and accessories. This will help ensure the accuracy and durability of the tester.

- Test the tester before use. It is a good idea to test the diesel compression tester before you use it. This will help ensure that it is working correctly and that you are familiar with its operation.

- Store the tester properly. When not in use, be sure to store the diesel compression tester in a safe place where it will not be damaged or misplaced.

- 【Precision in Pressure Readings】 Featuring a 0-1000 PSI/0-70 bar gauge with a release valve and flexible hose, this kit ensures accurate pressure measurements, facilitating effective diagnostic procedures.

- 【Enhance Diesel Engine Maintenance】 The Bicos Diesel Compression Testing Set simplifies tasks related to injector and glow plug replacements, making diesel engine maintenance more efficient.

- 【Versatile Compatibility】 With 9 glow plugs and 4 injector adaptors, our diesel compression tester caters to a diverse range of diesel vehicles, from trucks and cars to tractors, providing a comprehensive solution for diesel engine assessments.

- 【Bicos】 Bicos is here with excellent products. We doesn't accept compromises when it is going about quality. We does our utmost to provide the best possible solutions for your needs.

- COMPLETE TEST KIT: This diesel compression tester kit by Orion Motor Tech comes with a highly accurate diesel pressure gauge as well as all the necessary adapters and fittings to let you independently assess the condition of your engine's cylinders

- VERSATILE USE: Our diesel compression tester works with diesel engines on a wide range of vehicles including cars, trucks, ATVs, motorcycles, and more, thanks to the included glow plug adapters, injector adapters, and push-on connectors

- EASY-TO-READ DUAL GAUGE: The diesel pressure gauge features a shockproof rubber casing and a large dual-scale dial with readings in both psi and bars for easy and accurate readings on American and metric systems

- DURABLE MATERIALS: The adapters of our diesel injector tester are made of high-quality brass and metal for lasting strength and corrosion resistance, while the rubber hose endures high pressure and heat for your safe use

- EASY PORTABILITY: These diesel engine tools for mechanics come with a rugged blow-molded case, keeping everything organized and easy to store or transport between jobs

- The gauge has a range of 0-70 Bar/0-1000 Psi.

- Comes with 9 different glow plugs and 4 injector adaptors.

- Features a built in resetter and all adapters have a shortcut.

- Diesel Engine Compression Check: Easily check the compression of your diesel engine with our precision-designed tools to ensure optimal engine performance.

- QUICK FIT ADAPTER: With quick-fit design, it simplifies the connection process of the tool and saves your time and energy.

- Built-in Pressure Relief Valve: Equipped with a built-in pressure relief valve to ensure safe operation and minimize damage caused by improper operation.

- Flexible Hose (355mm): The flexible hose design makes the tool easier to maneuver and adaptable to various working environments.

- Dual Scale 80mm Diameter Dial: Equipped with a dual scale dial for easy reading of pressure values ranging from 0 - 1000 psi / 0 - 70 bar and a protective cover to ensure long term use.

- 1. Diesel Engine Compression Tester Kit:Professional-grade design tools enable convenient detection of diesel engine compression ratios, quickly identifying abnormal cylinder pressure issues. Ensure the engine always operates at high efficiency, effectively improving fuel economy and power output stability.

- 2. Perfect Design:Innovative quick-connect adapter structure supports tool-free rapid installation, significantly simplifying the connection process between the detection equipment and the engine.

- 3. Built-in Safety Pressure Relief Device:Equipped with an independent pressure relief valve that automatically triggers when the pressure exceeds the safe threshold during testing. This effectively prevents equipment damage and safety hazards caused by misoperation or abnormal high pressure in the cylinder, providing dual safety guarantees for the detection process.

- 4. High-quality materials:Features a high-elasticity, high-pressure-resistant hose (355mm in length) that can freely bend to adapt to complex spatial layouts in the engine compartment. It easily reaches detection points that traditional tools cannot access. The hose material is oil-resistant and wear-resistant, ensuring long-term high-frequency use without aging or cracking.

- 5. Diesel Compression Tester:Configured with a large 80mm-diameter dial for clear reading, simultaneously displaying dual-range scales in imperial (0-1000 psi) and metric (0-70 bar) units for intuitive and convenient reading.

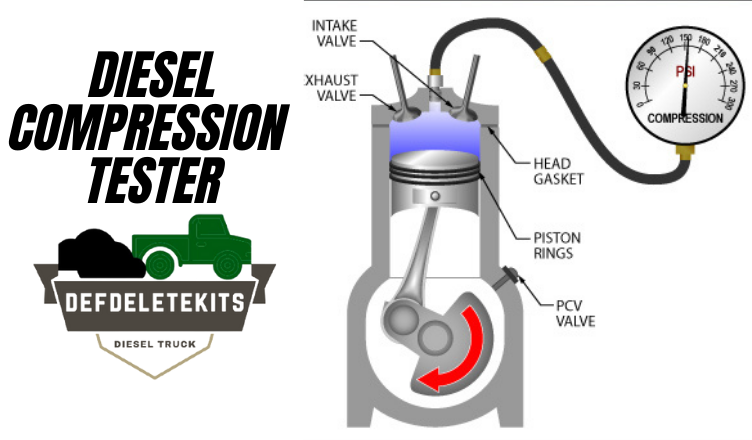

The engine compression test

An engine compression test is a tool that helps to determine the condition of an engine’s cylinders and pistons. The test measures the amount of pressure that is exerted on the piston as it moves up and down in the cylinder.

The results of the test can help to diagnose problems with the engine, such as worn or damaged cylinders and pistons. The test can also be used to identify leaks in the engine’s seals and gaskets.

The engine compression test is a key diagnostic step for diesel engines. The purpose of the compression test is to measure the pressure created by the cylinders as they compress the air-fuel mixture.

The higher the pressure, the more efficient the engine will be. A diesel compression tester is a specialized tool used to measure engine compression. The tester attaches to the spark plug hole and measures the pressure in pounds per square inch (PSI). The test results can help identify problems with the engine and help determine whether or not the engine is worth repairing.

The procedure for testing

Now that you know the basics of how a diesel engine works, we can move on to the testing procedure. The first step is to locate the compression tester adapter. This is typically a threaded fitting that is screwed into the engine block, near the spark plugs. The compressor hose is then connected to this fitting, and the other end of the hose is connected to the compression tester itself. The compressor hose must be tight so that there is no air leakage.

Once everything is connected, start the engine and let it run at idle. Next, place the compression tester gauge needle in the “COMPRESSION” area. The gauge should read between 0 and 300 psi (pounds per square inch). If it doesn’t, the engine isn’t compression-tested. The next step is to increase the engine speed to 2,000 rpm and hold it there for 10 seconds. The gauge should now read between 0 and 500 psi. If it doesn’t, then there is a problem with the engine.

Finally, release the engine speed to idle and check the gauge again. The reading should be back to 0 psi. This completes the compression test. Remember, if the gauge reads anything other than 0 psi, there is a problem with the engine that needs to be fixed.

How to Do an Engine Compression Test

If you’re unsure about the health of your car’s engine, a compression test is a great way to check its condition. This test measures the amount of pressure that builds up in the cylinders when the engine is running and can give you valuable insight into how well your engine is performing. Here’s a step-by-step guide on how to do an engine compression test:

- Prepare your vehicle. Make sure that your car’s battery is fully charged and that there is no oil or coolant leaking from the engine.

- Warm up the engine. This will help ensure accurate results.

- Disconnect the spark plug wires from the spark plugs and ground them so they don’t create a spark.

- Remove the spark plugs using a spark plug wrench.

- Install the compression gauge into the number 1 spark plug hole and screw it in by hand. Do not use any tools to tighten it, as you could damage the gauge.

- Turn on the ignition and wait for the engine to reach its normal operating temperature (between 75 and 100 degrees Celsius).

- Measure and record the compression pressure for each cylinder. You will need to do this twice – once with the throttle fully open and once with it fully closed. The results may vary depending on how worn your engine is.

- Compare your results to this chart to see if your engine is in good condition:

- Cylinder 1: 140-150 psi

- Cylinder 2: 135-145 psi

- Cylinder 3: 130-140 psi

- Cylinder 4: 125-135 psi

If the pressure in any of the cylinders is significantly lower than these numbers, it could be an indication that there is a problem with that cylinder. Common issues include worn piston rings, valves, or bearings.

Compression tests are a great way to get insight into the health of your engine. By following this guide, you can easily perform one and interpret the results to see if there are any issues that need to be addressed.

Conclusion

Diesel compression testers are valuable tools for mechanics and DIYers alike. By understanding the different types of diesel compression testers available and how to use them, you can make an informed decision when purchasing a tester for your specific needs. We hope this article has helped you better understand diesel compression testers and their uses. Have you tried using one? Let us know in the comments below.